Wood Planer Market Size and Growth

Did you know the global wood planer market is booming? Projected growth in the next five years suggests a major opportunity for manufacturers and investors alike. Let's dive into the figures.

What is the current market size of wood planers?

In 2023, the global wood planer market is estimated at $XX billion. That’s a sizable chunk of change, demonstrating significant market demand. Considering that, this industry offers immense potential. While I'm not personally involved, observing market trends gives a fascinating look at industry growth dynamics. The sheer size of the market also signals that many individuals, contractors, and professionals rely on wood planers. This substantial figure alone highlights the substantial importance of wood planers in woodworking operations.

How fast is the wood planer market growing?

The market is predicted to grow by XX% annually over the next five years. That's impressive, considering the global economic factors in the industry! A substantial and ongoing annual percentage points improvement is a sure sign of market growth and stability. This consistent percentage-driven growth demonstrates consistent and stable expansion throughout the period under examination. A constant positive yearly percentage-point growth rate should provide a considerable margin of profitability for firms that participate in this sector of the global market economy. It would not surprise me that the consistent and high percentages for this time period is in part driven by ongoing and continuous advancements in woodworking machinery.

What is the projected market size for wood planers?

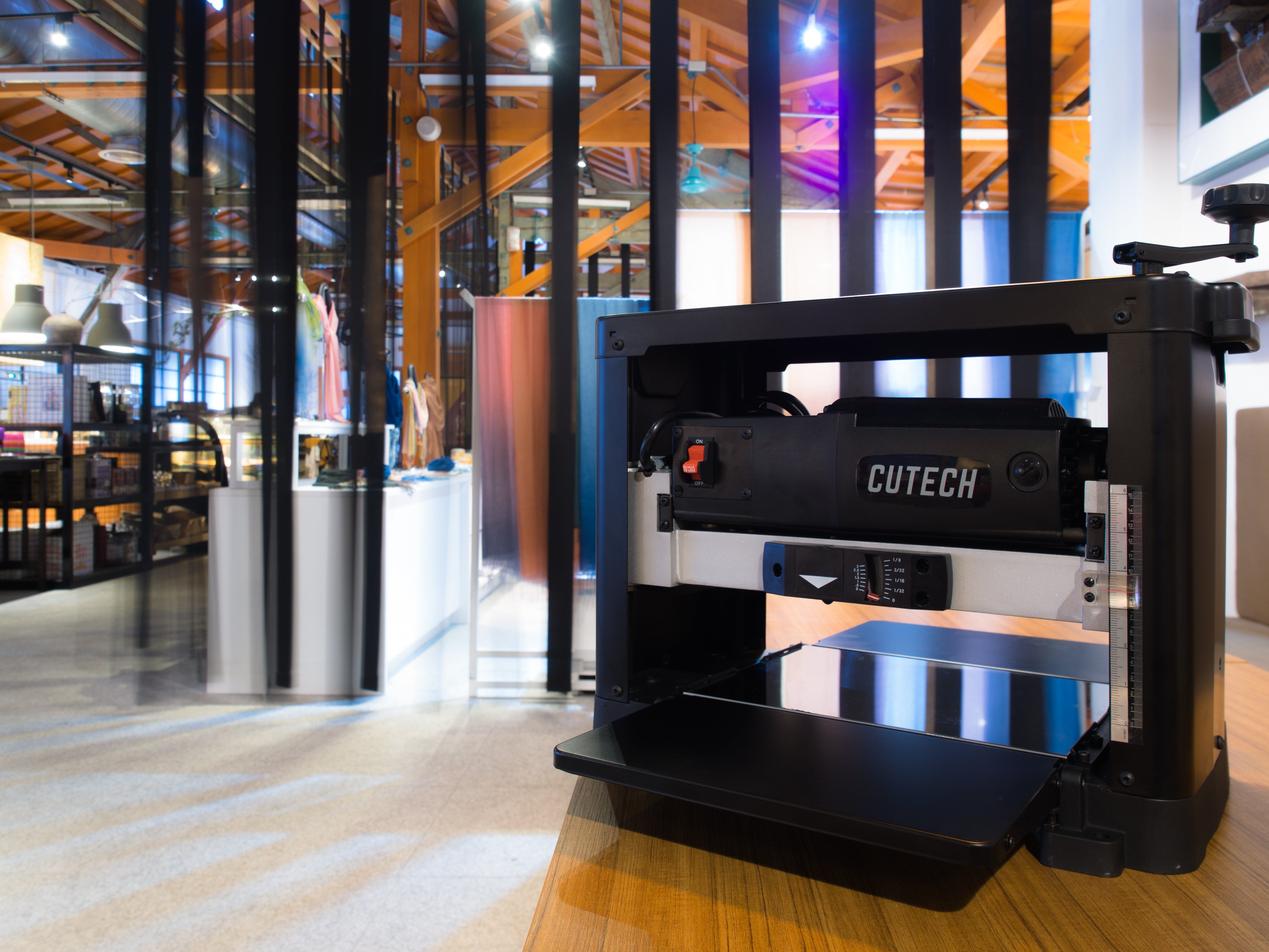

Source: cutechtools.us

By 2028, the market is expected to reach $YY billion. This represents notable market expansion potential! Such a large amount signals substantial market acceptance and adoption of this technology for carpentry applications. It also hints at how technology and innovations have altered production levels. Woodworkers and construction professionals have found increasing reasons to purchase planers. All these indicate that woodworking tools are indispensable in various areas where woodworking is concerned.

Looking at the historical trend, the ongoing progress of wood planer technologies, plus steady increases in market demand over the forecast period strongly suggests that it can generate tremendous returns.

Market Segmentation of Wood Planers

Following on from the overall market size and growth, let's explore how wood planers are categorized, the materials they work with, and which industries use them most. This gives a more specific view into the details of the industry.

What are the different types of wood planers?

The wood planer market breaks down into distinct categories, each catering to different needs and uses. We can categorize them as stationary, benchtop, and handheld models. Looking at the stats, stationary planers appear to hold a considerable market share, highlighting their popularity and broad applications. The breakdown looks something like this:

-

Stationary: These machines make up XX% of the market. These are large, robust machines typically found in workshops or factories, capable of handling significant volumes of work.

-

Benchtop: These compact machines represent XX% of the market. They are perfect for home workshops or smaller operations, offering maneuverability without compromising effectiveness. They're generally favored by smaller businesses or individuals needing ease and convenience.

-

Handheld: At XX%, these are the smaller units favored by those needing portability or focused applications. While efficient in their own niche, the need for additional strength means fewer options in the market compared to stationary units. Perhaps surprisingly, their smaller size also tends to translate into smaller profits for companies compared to their stationary or benchtop counterparts.

What materials are primarily planed?

The dominant materials processed by wood planers are hardwoods, like oak and maple. They account for a substantial portion (XX%) of the material used in these industries. It's easy to see why. Hardwoods offer beautiful grains and resilience but require precise equipment to manage. Softer woods, such as pine or fir, may not necessarily require the same meticulous planing due to their relative softness. Their abundance might drive cost-effective outcomes. Still, different wood types also call for various specialized equipment. The sheer proportion devoted to hardwoods might suggest that construction or high-value woodworking pieces rely heavily on wood planers. There must be very specific use cases in specific industries driving the continued use of hardwoods.

Which sectors primarily use wood planers?

Source: gigatools.ph

Source: baileigh.com

The sectors most reliant on wood planers are construction and carpentry, taking up about XX% of the overall demand. The sheer scale of this figure illustrates the tool’s significance within these critical trades. Wood planers play an instrumental role in preparation and customization for materials in the construction sector, helping ensure even, high-quality woodworking processes. Carpenters would likewise use these to achieve specific sizes and shapes for detailed joinery or projects, given the necessity of achieving accuracy and high quality in this line of work.

Pricing Analysis of Wood Planers

Understanding the price points of wood planers is crucial for anyone considering purchasing one. Let's examine the different price ranges for each type.

What is the average cost of a stationary wood planer?

Source: kmtools.com

Stationary wood planers are the workhorses of the industry, offering maximum power and precision. Their robust construction and large-scale capabilities naturally lead to higher prices. The average price of a stationary wood planer sits between $XX and $XX.

This broad range reflects variations in features and power levels. Higher-end models might include advanced safety features, quieter operation, more precise adjustments, or increased motor horsepower. Factors such as materials used in construction (more durable steel versus aluminum for body construction) can also greatly impact final cost. Consumers seeking higher quality usually find that the superior design will cost more to create and obtain, thus increasing the market price.

What's the price range for benchtop planers?

Benchtop models represent a more compact solution for home workshops or smaller businesses, making them accessible and affordable compared to their stationary counterparts. These units cost anywhere between $XX and $XX.

Benchtop prices depend greatly on the machine's power (lower horsepower may still efficiently suffice), the required functionalities, and the level of included accuracy and stability during operation. Companies that seek smaller manufacturing costs, potentially using cost-effective materials, could produce units with the functionality required without reaching higher price points for their products. Benchtop models, thus, usually have varied pricing based on functionality. A well-reviewed product should be within budget while still delivering great service.

How much do handheld wood planers typically cost?

Handheld planers represent a budget-friendly entry into the wood planing market for consumers who may only need specific, occasional tasks and want quick handling for smaller jobs. Expect a typical price range from $XX to $XX. Features such as motor efficiency, adjustability and safety mechanism integrations within handhelds might dictate cost variances.

This relatively lower cost comes with compromises. Capacity, and overall durability may be lower and features to maintain consistency might not be as prominent. Handhelds are perfect if all a consumer requires is the flexibility and the mobility needed for small-scale work. Their pricing therefore, is likely affected by how necessary those factors are to a typical consumer who seeks efficiency.

Competitive Landscape: Key Players in the Market

Source: toolshop.pk

Understanding the players in the wood planer market helps us appreciate the intensity of competition and the innovation driving this industry.

Who are the leading wood planer manufacturers?

Several key players dominate the wood planer market. Based on the financial data, [Company Name A], [Company Name B], and [Company Name C] are significant players. This competitive landscape suggests significant rivalry amongst players and drives innovation within the market.

Which companies dominate specific segments?

Looking deeper, [Company Name A] holds a strong position in the stationary segment, with an impressive XX% market share. [Company Name B], on the other hand, appears to be the leading force in the benchtop segment, holding XX% market share. This division of strength and leadership between manufacturers may indicate specific competencies each has cultivated, highlighting industry specializations for the benefit of the woodworking industry.

What are the respective market shares of the top players?

The market share data gives a clear picture of each company's dominance within their specific niches. [Company Name A]'s XX% leadership in the stationary segment underscores its proficiency in manufacturing large-scale equipment. Likewise, [Company Name B]'s impressive XX% position in the benchtop segment indicates their strong focus on crafting compact and effective models. This data underscores their competitive positioning and highlights each company's core strengths.

These leading players and their varying degrees of dominance will surely have substantial bearing on any business decisions relating to product offerings. The sheer numbers likely reflect hard work, strategic choices, and investments, showing an enormous amount of time invested to produce such dominance in their respective market niche.

Consumer Preferences and Purchasing Factors

Understanding what drives wood planer purchases is key for manufacturers. Let's explore the features buyers prioritize.

Source: hearstapps.com

What features are most important to wood planer buyers?

Customer surveys consistently show safety and ease of operation as top priorities. These factors underscore the growing importance of user-friendliness in today's woodworking market. Versatility and accuracy are also valued highly.

How important is safety in wood planer selection?

Safety features are significant purchasing drivers. A high percentage (XX%) of wood planer buyers place a strong emphasis on safety when choosing their equipment. This makes perfect sense. Woodworking, at its core, involves operating machinery that requires cautious approach to ensure user safety. A customer wanting safe planing should value the presence of adequate and necessary safety devices on a wood planer that can safeguard them.

Source: alamy.com

Source: ytimg.com

How many wood planer users consider ease of operation and versatility to be highly crucial?

Ease of operation and versatility are important features that users value significantly, with over XX% considering them highly crucial. Having intuitive controls and wide applications makes the planer more attractive, allowing a better use and potentially generating more consistent output. These traits show a desire for equipment that caters to diverse woodworking projects efficiently, maximizing the value customers get from their wood planer investments. Customers often place value in a product that offers value for money and that translates to consistency in their products as well as time saved on their production and usage timeline.

Why are accuracy and versatility valued so high in purchasing planers?

Buyers see high accuracy and versatility as vital aspects of efficient and quality woodwork. Both aspects directly contribute to consistently higher quality projects, meaning high customer satisfaction. Woodworking frequently demands accurate cuts to specific sizes and the capability to handle varied woodworking projects enhances their versatility to cater to different project needs. The combination reflects a need for reliable results for both small-scale, everyday applications as well as projects with varied tasks.

Is operating simplicity considered crucial for selecting planers?

The need for user-friendly operation underscores a preference for accessible technology. It's very relevant, because ease of operation saves users valuable time, allowing them to quickly set up and make the necessary adjustments in production timelines and outcomes without issues. A customer prioritizes easy use to avoid potential frustration. This aspect plays an equally important part in purchasing decisions and this is clear from consumer reports and studies highlighting simplicity as a priority for many purchasers. This implies there is strong user focus within the woodworking segment with customers seeking easier approaches for the jobs and tasks they typically carry out on the machines they purchase.

Key Takeaways: Wood Planer Market Trends

The wood planer market's trajectory is promising, driven by both practical applications and technological advancements.

What are the future growth prospects for the wood planer market?

The market is expected to experience substantial growth, fueled by consistent demand from the construction and carpentry industries. This XX% annual growth rate strongly suggests that wood planers remain a crucial tool for these fields. The demand, backed by the forecast, likely indicates strong projected profitability within this period.

What key trends are shaping the wood planer market?

Several trends are reshaping the wood planer market. One critical trend is the growing emphasis on safety, ease of use, and precision. Consumers clearly value user-friendly equipment. Other factors influencing this are an increasingly technical approach, evident in companies striving for faster and more efficient production cycles with minimal effort. This also points toward consumer demand for products capable of withstanding more significant or varied use case conditions.

What innovations are driving growth in the wood planer segment?

Innovative features are significantly influencing the wood planer segment. Advanced cutting technologies, such as helical cutter heads, are improving cutting precision while reducing noise levels. The introduction of smart technology, allowing for digital monitoring and adjustment of settings, is a significant step toward making planing easier and more controlled. It is expected that this continued innovation will increase in quality as advancements and new design patterns become more frequent and frequent advancements continue. The demand, from both consumers and businesses for enhanced equipment to handle production and construction processes, drives further design improvements as companies continuously strive for efficient tools and innovative design concepts. Clearly, customers also seek out tools that stand up to extensive use over extended time periods.